| Model | B01-2 |

| Power | AC 220V 50/60Hz |

Rated Power | 3.0KW |

Temp Control | No segment adjustable, normal temperature ~700 °C |

Speed | 1~23m/min |

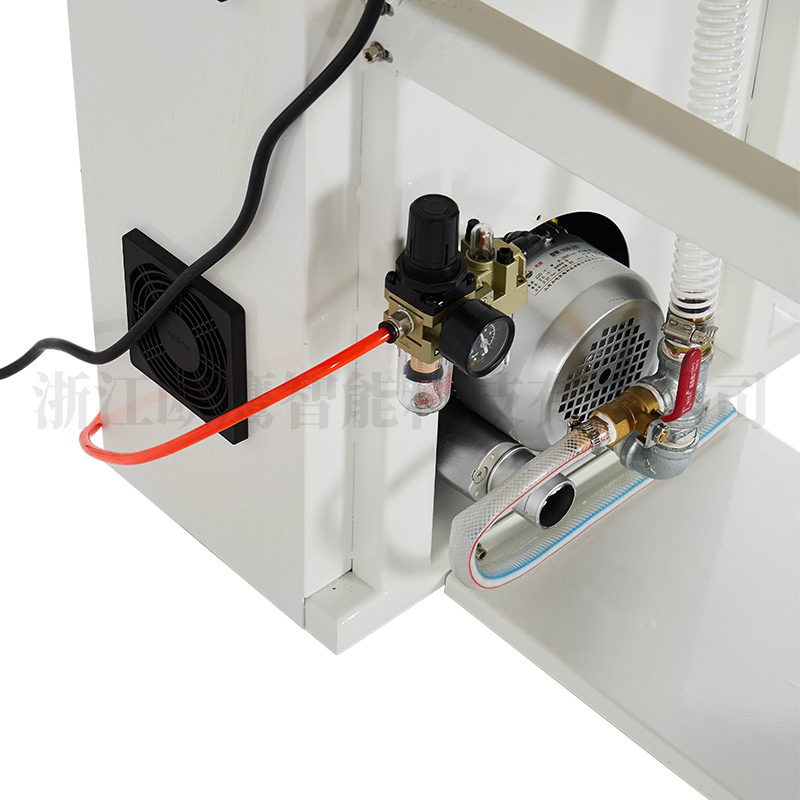

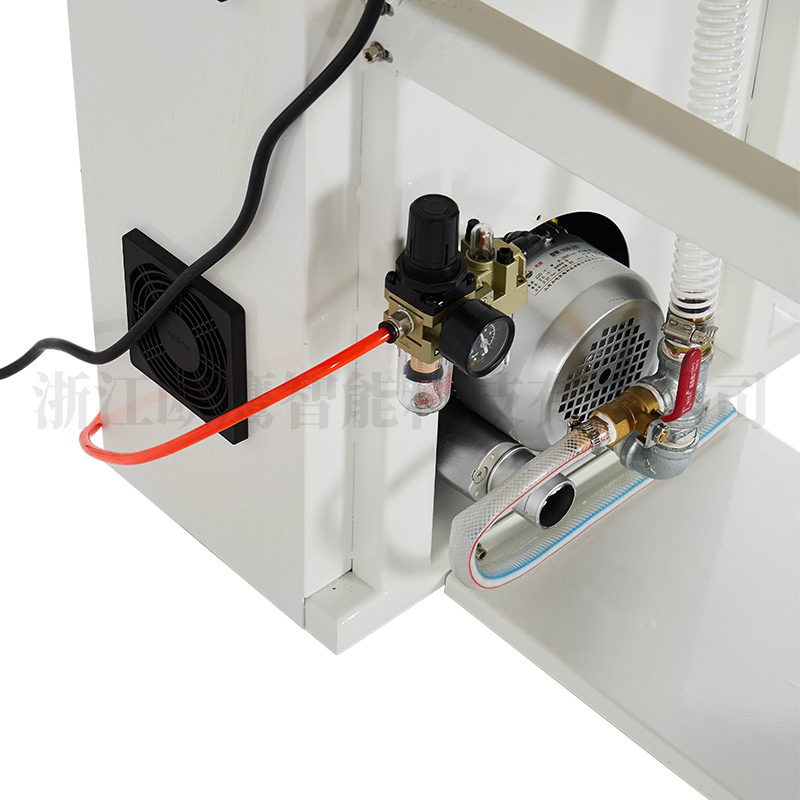

| Air Pressure | 0.35~0.5 Mpa |

Roller Width | Smooth surface 25mm standard type, other options such as steel grain, straight grain need special making, etc |

| Tape Width | Standard type 14mm~20mm, other widths can be freely selected according to customer needs |

Lifting Distance | 10~30mm |

Size | 1150mm×610mm×1550mm |

| NW | 150kg |

| Stitching Leakage Prevention | There are available adjustments between the hot air duct inward movement and the roller start and the rolling wheel stop and the hot air duct outward movement to prevent the slot jump from leaking. |

| Model | B01-2 |

| Power | AC 220V 50/60Hz |

Rated Power | 3.0KW |

Temp Control | No segment adjustable, normal temperature ~700 °C |

Speed | 1~23m/min |

| Air Pressure | 0.35~0.5 Mpa |

Roller Width | Smooth surface 25mm standard type, other options such as steel grain, straight grain need special making, etc |

| Tape Width | Standard type 14mm~20mm, other widths can be freely selected according to customer needs |

Lifting Distance | 10~30mm |

Size | 1150mm×610mm×1550mm |

| NW | 150kg |

| Stitching Leakage Prevention | There are available adjustments between the hot air duct inward movement and the roller start and the rolling wheel stop and the hot air duct outward movement to prevent the slot jump from leaking. |